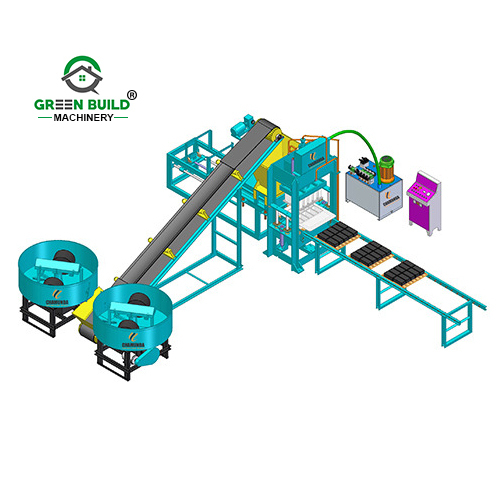

फà¥à¤²à¤¾à¤ à¤à¤¶ बà¥à¤°à¤¿à¤à¥à¤¸ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨

Price 1100000 आईएनआर/ टुकड़ा

फà¥à¤²à¤¾à¤ à¤à¤¶ बà¥à¤°à¤¿à¤à¥à¤¸ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨ Specification

- प्रॉडक्ट टाइप

- Brick Making Machine

- सामान्य उपयोग

- औद्योगिक

- मटेरियल

- क्षमता

- पीसी/घंटा

- वजन (किग्रा)

- टन

- टाइप करें

- कम्प्यूटरीकृत

- ऑटोमेटिक

- हाँ

- तरीका

- वाइब्रेशन टाइप

- कंपन की आवृत्ति

- हर्ट्ज (एचजेड)

- अधिकतम दबाव

- पीएसआई

- मशीन पावर

- किलोवोल्ट-एम्पी (केवीए)

- वोल्टेज

- 230 वोल्ट (v)

- आयाम (एल* डब्ल्यू* एच)

- फुट (फुट)

- पैलेट का आकार

- 700-600

- न्यूनतम ऊंचाई

- मिलीमीटर (mm)

- अधिकतम ऊंचाई

- मिलीमीटर (mm)

- ईंटों की संख्या

- 10

- फ़ीचर

- , हाई टिकाऊपन

- रंग

- WHITE/BLUE

- वारंटी

- 1 वर्ष

फà¥à¤²à¤¾à¤ à¤à¤¶ बà¥à¤°à¤¿à¤à¥à¤¸ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨ Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- एफओबी पोर्ट

- Morbi

- भुगतान की शर्तें

- , ,

- आपूर्ति की क्षमता

- 50 प्रति वर्ष

- डिलीवरी का समय

- 7 - 10 दिन

- नमूना उपलब्ध

- Yes

- नमूना नीति

- पैकेजिंग का विवरण

- full packing

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

- प्रमाणपत्र

- iso/msme

About फà¥à¤²à¤¾à¤ à¤à¤¶ बà¥à¤°à¤¿à¤à¥à¤¸ मà¥à¤à¤¿à¤à¤ मशà¥à¤¨

ðŸ Popular Manufacturers (India & Global)

-

REVA Engineering Enterprises

-

Laxmi Engineering

-

Sadhana Engineering

-

Q Green Techcon

-

Hydraform (Global)

… Benefits of Fly Ash Bricks

-

Eco-friendly (utilizes waste material)

-

Better thermal insulation

-

Uniform size and shape

-

Less water absorption than clay bricks

If you™re looking for machine suggestions, prices, or suppliers, I can search the latest data online or help you compare specific models. Would you like me to do that?

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in ईंट बनाने की मशीन Category

सीमेंट ब्रिक्स बनाने की मशीन

वारंटी : 1 वर्ष

फ़ीचर : हाई टिकाऊपन

ऑटोमेटिक : हाँ

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

हाइड्रोलिक ब्रिक्स बनाने की मशीन

वारंटी : 1 वर्ष

फ़ीचर : हाई टिकाऊपन

ऑटोमेटिक : हाँ

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

हाई प्रेशर ब्रिक्स मेकिंग मशीन

वारंटी : 1 वर्ष

फ़ीचर : हाई टिकाऊपन

ऑटोमेटिक : हाँ

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

औद्योगिक ईंट बनाने की मशीन

वारंटी : 1 वर्ष

फ़ीचर : हाई टिकाऊपन

ऑटोमेटिक : हाँ

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese